|

|

||||||||

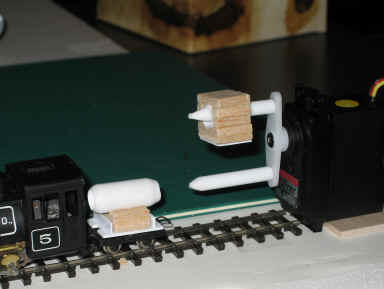

| I've been working on a "load swapper" for a future

layout. The idea is that the loco will push a flatcar loaded with

a large wine barrel into an enclosed loading dock. The dock

services the wine bottling and shipping operations. While the

flatcar is in the dock, the "load swapper" will remove the

barrel and replace it with a stack of cases of wine to be shipped.

When the loco retrieves the flatcar, the new load will be on it.

All this will happen without any visible intervention.

The mechanism includes two servos of the type used in Radio Controlled model airplanes and a Picaxe microprocessor controller programmed to detect the presence of the flatcar in the loading dock, get input from the operator regarding the desired function, and carry out that function. Operations include:

The microprocessor is triggered by a magnet on the bottom of the flatcar which closes a magnetically operated reed switch located under the track. When it detects the presence of the flatcar, it shuts off the track power and illuminates a red LED to ask the operator which operation is desired. A Sony TV remote control is used to issue commands to the microprocessor. Use of the TV remote eliminates the necessity to build a special control panel. The load swapping servo has two "spears" and the incoming load will be "speared" as the flatcar enters the loading dock. Each load has a longitudinal hole to allow it to be "speared." Once the load is speared, a simple 180 degree rotation swaps the loads. A 90 degree rotation parks the loads. A second servo, located beneath the track, operates an uncoupling ramp when the operator wants to leave the flatcar in the loading dock. Many thanks to Larry Geib of Portland, OR, who talked me into trying the microprocessor, then coached me through building the board and programming it. I will be posting a tutorial that Larry prepared to guide me on this site in the near future. A video in WMV format showing the various load swapping operations is available below. Just click the picture and watch. This is about a 7 mb file, so you should have a broadband connection to view it. |

||||||||

|

|